Comparison of several welding structures between stainless steel heat exchange tube and tube sheet

2467views

2467views  2020-05-11

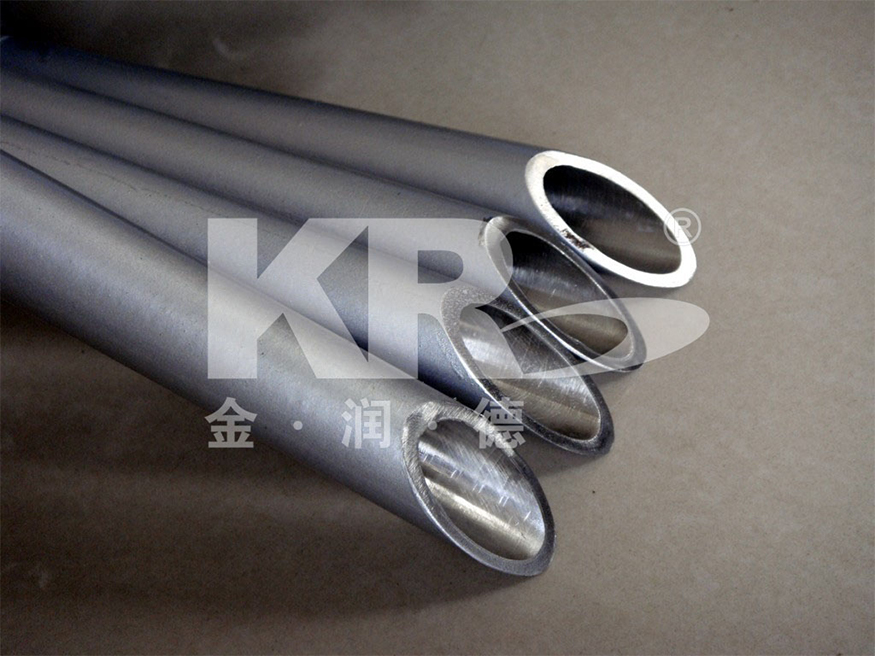

2020-05-11 The welding structure of stainless steel heat exchange tube and tube sheet can be divided into two types: front side and back side. Which structure to choose depends on the specific service conditions i.e. whether there is gap corrosion (the gap between the stainless steel heat exchange tube and the tube sheet hole) as well as the processing mechanical properties and welding me

Weld formed on the front of one tube plate

Compared with the back welding the front welding process and welding alignment are simple but whether it is expansion or not there is the problem of stress concentration at the root of the weld after the front welding and the gap between the heat exchange tube and the tube sheet hole cannot be completely eliminated so there is the condition of gap corrosion.

As shown in the above two screenshots "weld formed on the front" can be divided into:

1. Front fillet weld type

The tube end of the heat exchange tube extends out of the tube plate which can form welds of various weld leg height sizes. The size of the welding leg needs strength check which is convenient for calculation and adjustment.

This kind of structure can be welded manually or automatically. In multi pass welding visual inspection and Pt can be carried out after backing welding to control the quality of root weld.

In addition this structure can extend the pipe end out of the pipe plate long enough in advance during manufacturing. After welding the pipe end of the whole pipe plate can be machined to make all the pipe end faces on the same horizontal plane. This kind of structure can be used for the heat exchanger and condenser with vertical installation of uniform liquid film on the inner wall of the pipe required in the production process.

However the disadvantage of this fillet weld is that due to the protruding tube end compared with the structure of smooth heat exchange tube and tube plate at the inlet and the end of heat exchange tube sinks it will produce a large reduction of the inlet section (as is the case in the reference literature which is not understood by the individual) and there may be medium erosion at the nozzle.

Article address:http://krdpipe.com/newsdetail/4.html

Please indicate the source of Reprint:Jinrunde heat exchanger tube official website

Location:

Location: