904L Stainless steel welded pipe

Kingride stainless steel heat exchanger tubes have reliable quality high precision and corrosion resistance. The products are widely used in petrochemical biological pharmaceutical environmental protection water treatment industrial heat exchange and other fields.

1. Material of stainless steel welded pipe: 304 / 304L 316L 310S 321 904L 2205 / 2507 etc.

2. Source of raw materials: all meet the requirements of relevant national standards and the materials are from Jiugang TISCO Zhangpu Dongte etc.

3. Welding method: argon arc welding (TIG) plasma welding (PAW) submerged arc welding (SAW) etc. one or more of which are combined.

4. Executive standard: stainless steel welded steel pipe for fluid transportation (GB / t12771-2008).

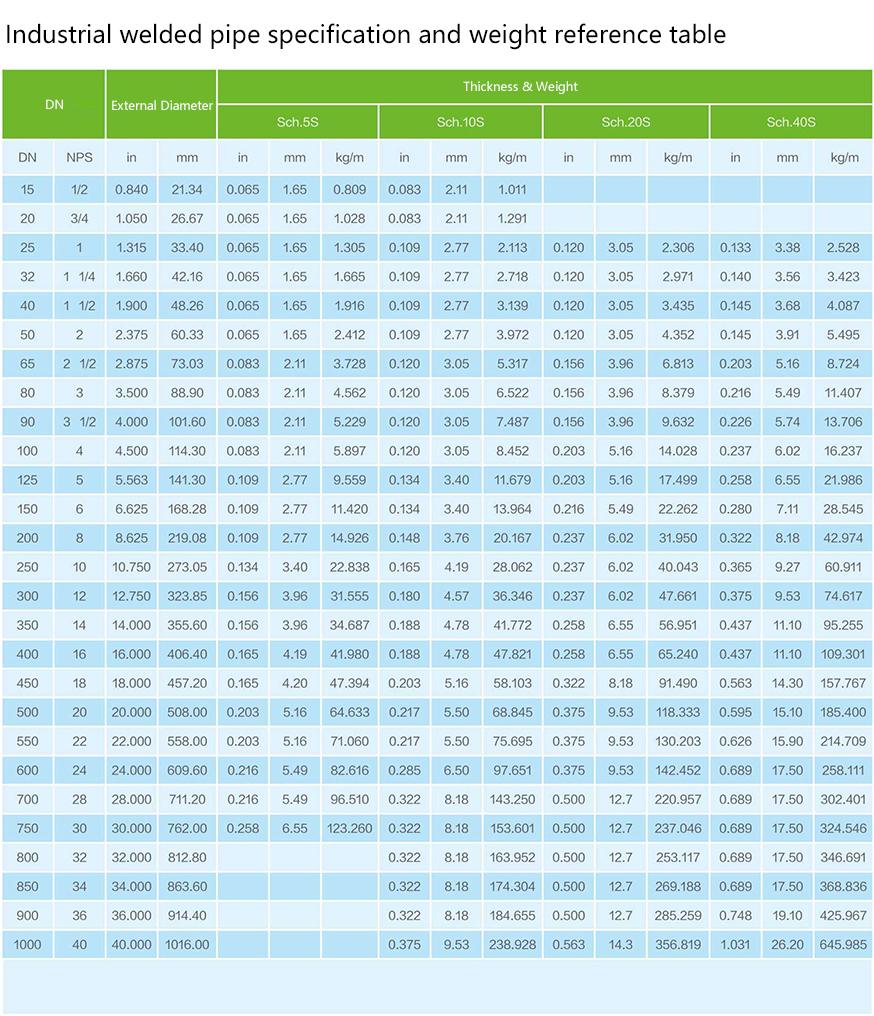

5. Production capacity: O.D: φ 12 ~ φ 3250mm wall thickness (W.T): 0.5 ~ 45.0mm.

6. Production process: raw materials - slitting / flattening - welding pipe making - end repairing - polishing / passivating - packaging - delivery (warehousing) accompanied by inspection at all li

7. Quality system System: the company has ISO9001 quality management system certification and pressure pipe component manufacturing license. And Kingride company has a sound quality inspection control system equipped with industrial CT chemical analysis eddy current testing water pressure testing air tightness testing universal testing universal testing machine and other inspection li

8. Application: construction industry food and medical industry sewage treatment petroleum and petrochemical industry papermaking electric power heat exchanger condenser water supply and water supply military industry marine industry aerospace industry etc.

9. About transportation: general transportation baling without package transportation; special transportation baling and outsourcing (package box protective container) transportation. For other special requirements please contact online customer service or call: 18615108063.

Location:

Location: